Bonding

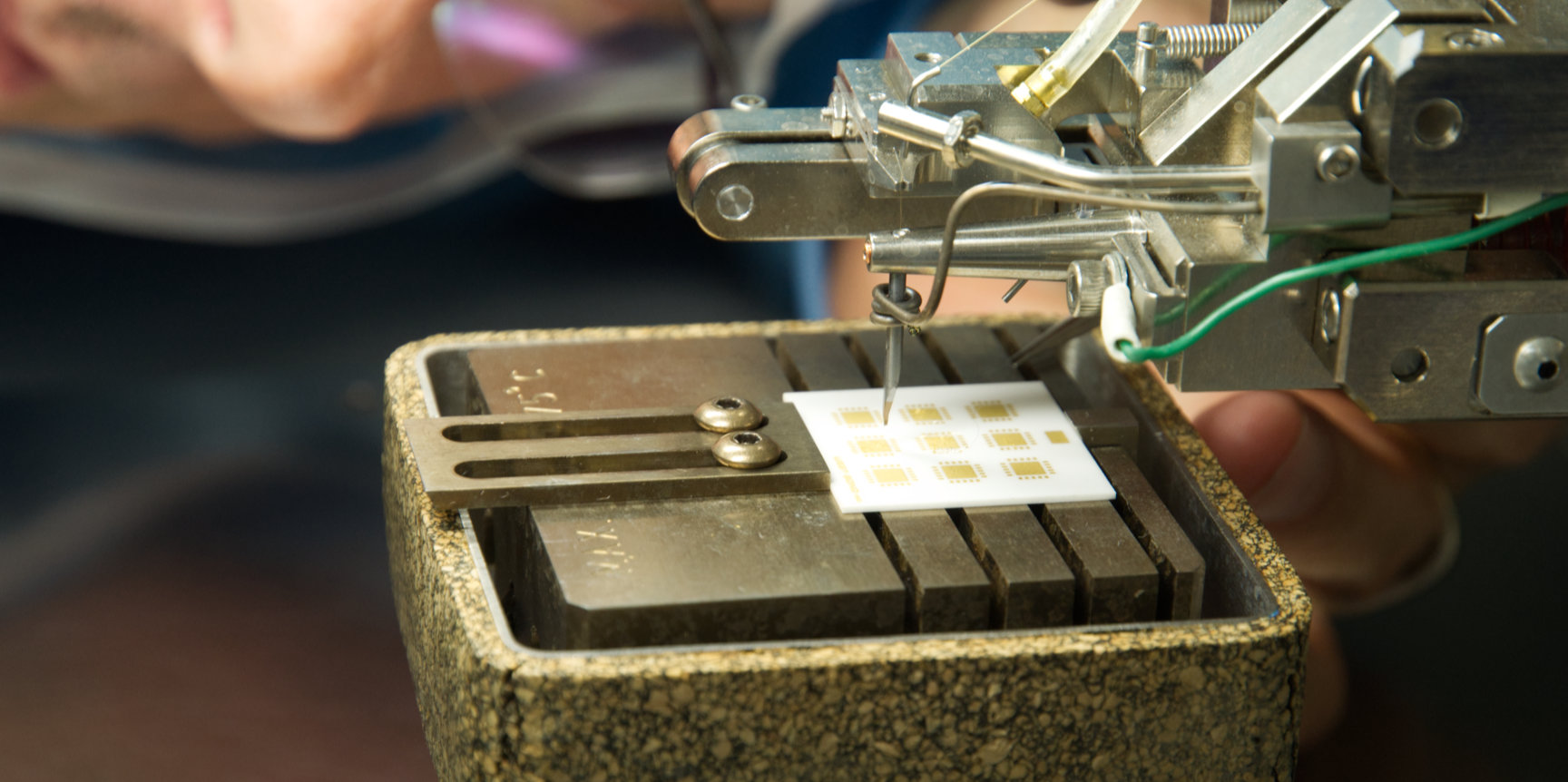

Wire bonder creating an electrical contact on chip level.

Responsibility:

- Wire wedge bonding of 25 mue Gold wires

- Deep access tool for bonding in packages

- Part size up to 200 x 200 mm2

- Ribbon bonding tools for HF-applications (Option on request)

- Heated workholder (2") for clamping plates and DIL-packages

- Bonder and work place ESD (Electro Static Discharge) save for sensitive applications

- Ionizer (fan) for neutralize static charges on surfaces / devices

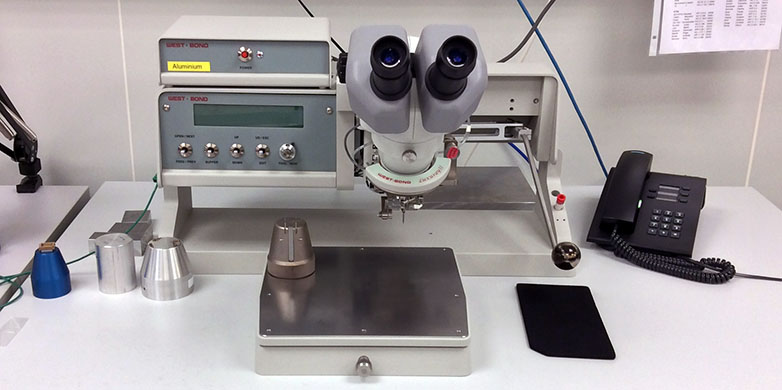

Responsibility:

- Wedge bonding of 25 mue Aluminium wires

- Deep access tool for bonding in packages

- Part size up to 200 x 200 mm2

- Heated workholder (50 x 50 mm2) for clamping plates and DIL-packages

- Bonder and work place ESD (Electro Static Discharge) save for sensitive applications

- Ionizer (fan) for neutralize static charges on surfaces / devices

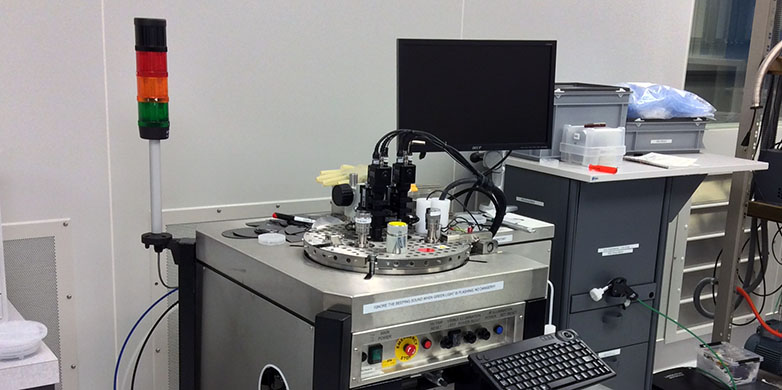

Responsibility:

- Wedge bonding of 25 mue Gold wires

- Deep access tool for bonding in packages

- Semiautomatic bonding process (Y- and Z-Axis motorized)

- Heated workholder with vacuum chuck (diameter 80 mm2) for clamping substrates

- Bonder and work place ESD (Electro Static Discharge) save for sensitive applications

- Ionizer (fan) for neutralize static charges on surfaces / devices

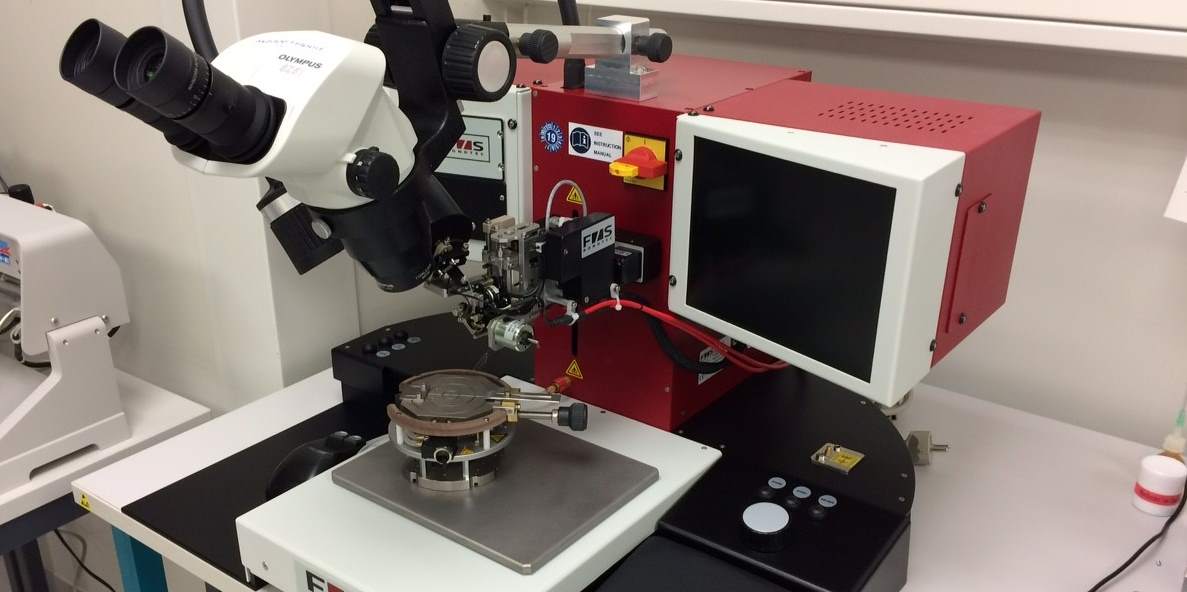

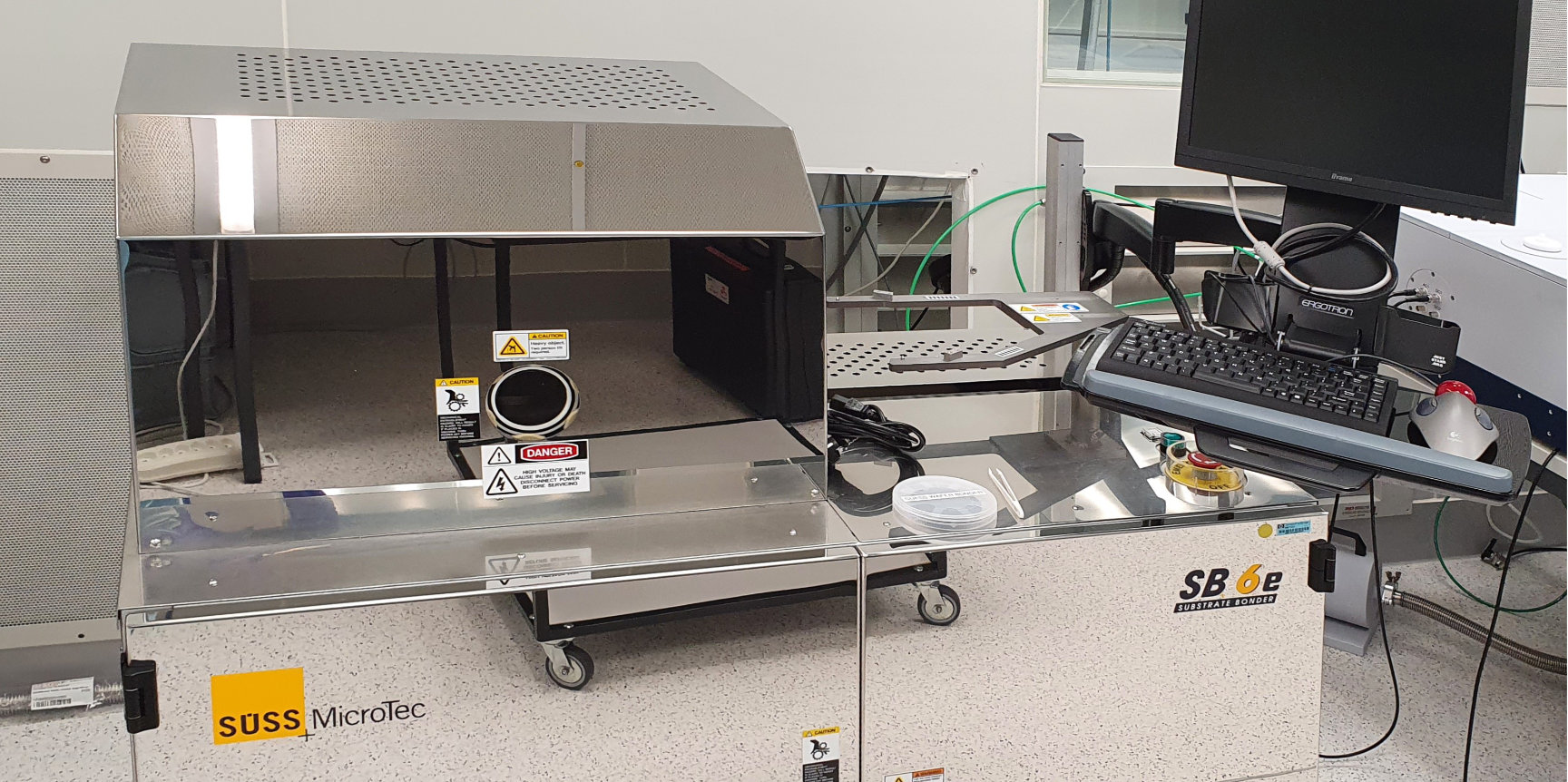

Responsibility:

- Thermocompression, anodic, eutectic and adhesive wafer bonding possible for up to 3'' wafers and smaller pieces (down to ~10x10 mm2)

- Up to 20 kN force for full wafers (maximum force scales with sample size)

- Maximum temperature 500 °C, programmable temperature ramps, temp. uniformity +/- 2%

- N2 purge/cooling gas

- Chamber pressure control during bonding from atmospheric down to 5*10-5mbar (turbo pump)

- SiC clamping plate for homogeneous force and temperature distribution

- Automatic operation (recipes) with live plots of process parameters